ZERO LIQUID DISCHARGE - ZLD

By SARTIME HOROLOGICAL (P) LTD

95+ % RO Recovery, 24x7 Availability

All grades of water including MB < 2ppm

Reduction in water consumption 50% by audit

15 years of uninterrupted service

9+ Inventions in water Recycling

All our customers are repeat customers

Zero Liquid discharge (ZLD) is the buzzy word in the plating industry. ZLD is normally associated with high cost of operation, High Capital cost. Invariably difficult to maintain.

We would like to share our experience after having running 4 plants & having installed 20 units with the below performance. 95+% recovery of water, 24x7 availability of required water quality. Because of high recovery, the evaporation cost has become very low. Evaporator is 2to3 days a week is operated.

We also would like to discuss process intensification in layout (foot print reduction), in operation of Cr6+ with SMBS reduction of 50%.

The OBR for DM+MB is 2000m3 or once 20 days. These processes are SCADA operated.

Technology of ZLD

1. The ZLD process creates solid waste out of wastewater by using two devices – evaporators and crystallisers. Evaporators can concentrate brines up to 2,50,000 ppm. TDS.

2. When the brine concentration exceeds 2,50,000 ppm TDS,

3. The brine is subsequently released in to a vessel where the pressure falls. As a result, the- remaining water boils and the salt crystallise, The cake of salt thus formed is then disposed of in landfill.

All grades of water including MB < 2ppm

Reduction in water consumption 50% by audit

15 years of uninterrupted service

9+ Inventions in water Recycling

All our customers are repeat customers

Zero Liquid discharge (ZLD) is the buzzy word in the plating industry. ZLD is normally associated with high cost of operation, High Capital cost. Invariably difficult to maintain.

We would like to share our experience after having running 4 plants & having installed 20 units with the below performance. 95+% recovery of water, 24x7 availability of required water quality. Because of high recovery, the evaporation cost has become very low. Evaporator is 2to3 days a week is operated.

We also would like to discuss process intensification in layout (foot print reduction), in operation of Cr6+ with SMBS reduction of 50%.

The OBR for DM+MB is 2000m3 or once 20 days. These processes are SCADA operated.

Technology of ZLD

1. The ZLD process creates solid waste out of wastewater by using two devices – evaporators and crystallisers. Evaporators can concentrate brines up to 2,50,000 ppm. TDS.

2. When the brine concentration exceeds 2,50,000 ppm TDS,

3. The brine is subsequently released in to a vessel where the pressure falls. As a result, the- remaining water boils and the salt crystallise, The cake of salt thus formed is then disposed of in landfill.

Product Description

95+ % RO Recovery, 24x7 Availability

All grades of water including MB < 2ppm

Reduction in water consumption 50% by audit

15 years of uninterrupted service

9+ Inventions in water Recycling

All our customers are repeat customers

Zero Liquid discharge (ZLD) is the buzzy word in the plating industry. ZLD is normally associated with high cost of operation, High Capital cost. Invariably difficult to maintain.

We would like to share our experience after having running 4 plants & having installed 20 units with the below performance. 95+% recovery of water, 24x7 availability of required water quality. Because of high recovery, the evaporation cost has become very low. Evaporator is 2to3 days a week is operated.

We also would like to discuss process intensification in layout (foot print reduction), in operation of Cr6+ with SMBS reduction of 50%.

The OBR for DM+MB is 2000m3 or once 20 days. These processes are SCADA operated.

Technology of ZLD

1. The ZLD process creates solid waste out of wastewater by using two devices – evaporators and crystallisers. Evaporators can concentrate brines up to 2,50,000 ppm. TDS.

2. When the brine concentration exceeds 2,50,000 ppm TDS,

3. The brine is subsequently released in to a vessel where the pressure falls. As a result, the- remaining water boils and the salt crystallise, The cake of salt thus formed is then disposed of in landfill.

All grades of water including MB < 2ppm

Reduction in water consumption 50% by audit

15 years of uninterrupted service

9+ Inventions in water Recycling

All our customers are repeat customers

Zero Liquid discharge (ZLD) is the buzzy word in the plating industry. ZLD is normally associated with high cost of operation, High Capital cost. Invariably difficult to maintain.

We would like to share our experience after having running 4 plants & having installed 20 units with the below performance. 95+% recovery of water, 24x7 availability of required water quality. Because of high recovery, the evaporation cost has become very low. Evaporator is 2to3 days a week is operated.

We also would like to discuss process intensification in layout (foot print reduction), in operation of Cr6+ with SMBS reduction of 50%.

The OBR for DM+MB is 2000m3 or once 20 days. These processes are SCADA operated.

Technology of ZLD

1. The ZLD process creates solid waste out of wastewater by using two devices – evaporators and crystallisers. Evaporators can concentrate brines up to 2,50,000 ppm. TDS.

2. When the brine concentration exceeds 2,50,000 ppm TDS,

3. The brine is subsequently released in to a vessel where the pressure falls. As a result, the- remaining water boils and the salt crystallise, The cake of salt thus formed is then disposed of in landfill.

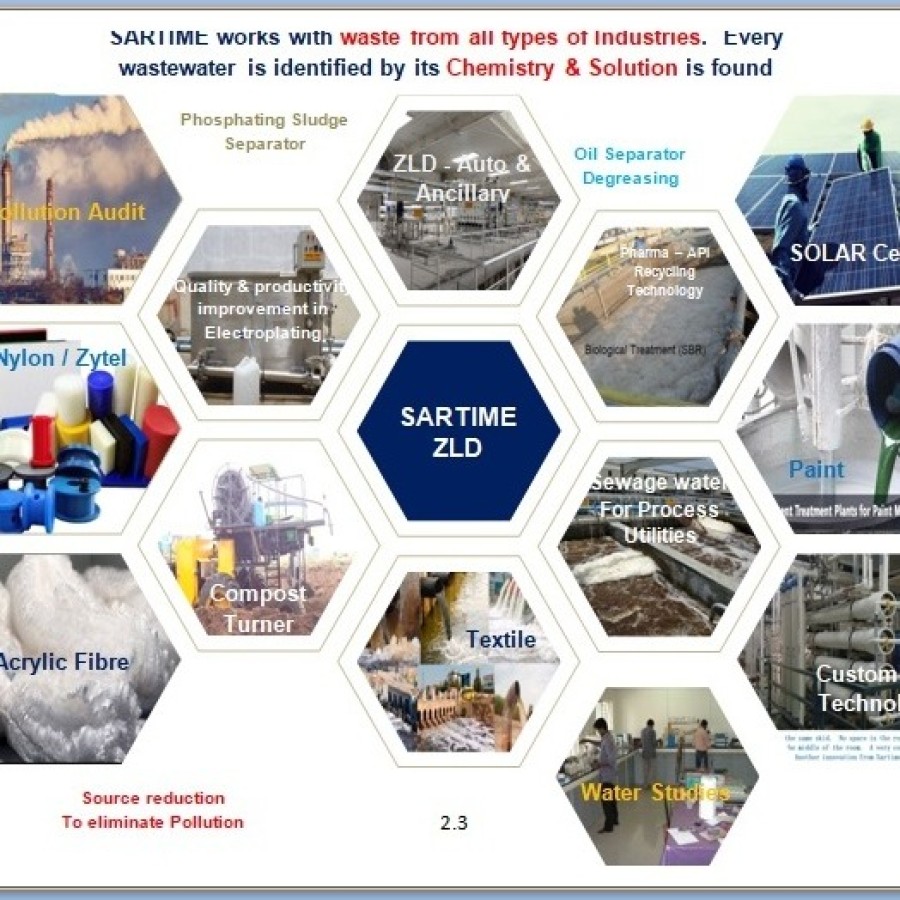

About the Company

Established in 1990 at Chennai, Tamil Nadu, India, we Sartime Horological Private Limited, are one of the leading manufacturers and exporters of Water Purification Plants & Systems. The complete product range we offer include ETP, RO Plants, Evaporator, UF, SBR, Advanced Membrane Separation System and Oil Separators or Skimmers. Further, we also offer Phosphate Sludge Separator, Compost Aero Tiller, Auto Spraying System.

Backed by well developed R & D activities and process approach as well as services of experienced industry professionals allow us to maintain a well defined process approach in each of the project handled by us. Based at studying performance of each of the equipment, we arrive at some process modifications that are not commonly used in Pollution Control Industry.

We meet the plant technology customization needs of our customers To understand and meet the critical equipment management related to pollution We hold expertise in studying both process and treatment scheme by studying the process and arriving at ideas to cut down waste at source itself By studying performance of each of the equipment, we can arrive at some process modifications that are not commonly used in pollution control industry by virtue of our well developed R & D activities Our well defined business approach helps us improves performance far beyond the conventional approach.

We adopt technologies that reduce costs as well as pollution, helping companies to be better placed to stay ahead of the competition If client’s effluent treatment/pollution problem is not solved by addition of equipment or any other strategy, it’s time they get in touch with us. We hold expertise in solving difficult Pollution Problems that others can’t.

Backed by well developed R & D activities and process approach as well as services of experienced industry professionals allow us to maintain a well defined process approach in each of the project handled by us. Based at studying performance of each of the equipment, we arrive at some process modifications that are not commonly used in Pollution Control Industry.

We meet the plant technology customization needs of our customers To understand and meet the critical equipment management related to pollution We hold expertise in studying both process and treatment scheme by studying the process and arriving at ideas to cut down waste at source itself By studying performance of each of the equipment, we can arrive at some process modifications that are not commonly used in pollution control industry by virtue of our well developed R & D activities Our well defined business approach helps us improves performance far beyond the conventional approach.

We adopt technologies that reduce costs as well as pollution, helping companies to be better placed to stay ahead of the competition If client’s effluent treatment/pollution problem is not solved by addition of equipment or any other strategy, it’s time they get in touch with us. We hold expertise in solving difficult Pollution Problems that others can’t.

Royal Enfield (A Unit of Eicher Motors)

April 09 2014, Sartime Horological Pvt Ltd, installed an STP, Effluent treatment system, 4-stage RO & Evaporator at our Oragadam plant.

The system has been running smoothly for a year, with 90–95% recovery from the RO and reused in the process.

Remaining water is evaporated and salts recovered, achieving zero liquid discharge.

Their operation and maintenance support has been satisfactory throughout.

Login to see seller contact details.

Product Reviews

More products by SARTIME HOROLOGICAL (P) LTD