Oil Separator for Degreasing bath / Soak Tank

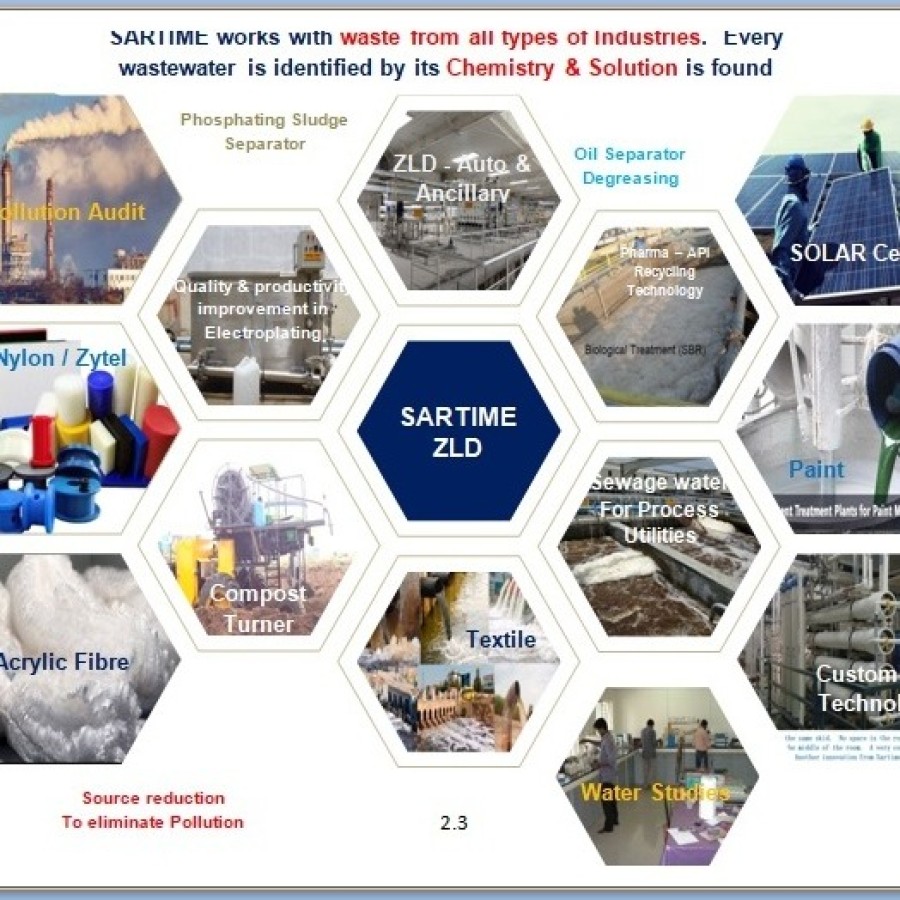

By SARTIME HOROLOGICAL (P) LTD

Unique features of SARTIME Oil Separator

It separates not only oil but also the sludge formed in the degreasing tank.

Advantages of Online Total Oil-Sludge Separation System

TOS keeps the bath consistently clean by removing oil & soil continuously while extending bath life to more than 13 months, in one case as long as 4 years.

1. QUALITY IMPROVEMENT IN FINISHING In the absence of On line Vat Sludge Separating system there will be no air agitation to the chemical baths. Since the sludge generation is removed on line Air agitation can be provided which will enable chemical to mix evenly and will not settle at the bottom. This will improve the finishing. Reduced usage of chemical for the same quantity of products results in reduce waste generation. We have seen rejections coming down by 70%.

2. CONSISTANCY IN QUALITY There will be no Monday quality and Friday quality. There will not be any powder formation & the finishing will be good.

3. IMPLEMENTATION OF KAIZAN & 6 SIGMA EASIER. Since the implementation of VSS is aimed at reducing the waste generation, Improvement in quality & elimination of stoppage of production for maintenance, this will contributes in achieving standards in Kaizan & 6 Sigmas.

4. REDUCTION OF CHEMICAL CONSUMPTION. Since no weekly cleaning is required, VSS will reduce the chemical wastage or consumption hence reduction of chemical usage. This is expected to be about 5%.

5. ELIMINATION OF PRODUCTION STOPPAGE FOR CLEANING. Implementation of On line Vat Sludge separating system will not require weekly cleaning of the chemical tank, which normally takes one shift loss. This will eliminate the one shift production loss. Besides other loss like power used for heating etc., due to keep the plant out of production will be eliminated.

6. E.T.P PROBLEMS REDUCED. Since the sludge is stored separately, this can be used as a phosphate fertilizer. If it is nickel free. These sludge will consume a lot of caustic to neutralize.

7. EXTENTION OF THE LIFE OF CHEMICAL BATH. The removal of sludge will eliminate at the tank bottom. On line removal of iron sludge from the chemical bath will increase the life of the chemical bath. As the life of the bath is also determined by the chemistry of the presence of the iron in the solution the exact increase in life may not be estimated.

It separates not only oil but also the sludge formed in the degreasing tank.

Advantages of Online Total Oil-Sludge Separation System

TOS keeps the bath consistently clean by removing oil & soil continuously while extending bath life to more than 13 months, in one case as long as 4 years.

1. QUALITY IMPROVEMENT IN FINISHING In the absence of On line Vat Sludge Separating system there will be no air agitation to the chemical baths. Since the sludge generation is removed on line Air agitation can be provided which will enable chemical to mix evenly and will not settle at the bottom. This will improve the finishing. Reduced usage of chemical for the same quantity of products results in reduce waste generation. We have seen rejections coming down by 70%.

2. CONSISTANCY IN QUALITY There will be no Monday quality and Friday quality. There will not be any powder formation & the finishing will be good.

3. IMPLEMENTATION OF KAIZAN & 6 SIGMA EASIER. Since the implementation of VSS is aimed at reducing the waste generation, Improvement in quality & elimination of stoppage of production for maintenance, this will contributes in achieving standards in Kaizan & 6 Sigmas.

4. REDUCTION OF CHEMICAL CONSUMPTION. Since no weekly cleaning is required, VSS will reduce the chemical wastage or consumption hence reduction of chemical usage. This is expected to be about 5%.

5. ELIMINATION OF PRODUCTION STOPPAGE FOR CLEANING. Implementation of On line Vat Sludge separating system will not require weekly cleaning of the chemical tank, which normally takes one shift loss. This will eliminate the one shift production loss. Besides other loss like power used for heating etc., due to keep the plant out of production will be eliminated.

6. E.T.P PROBLEMS REDUCED. Since the sludge is stored separately, this can be used as a phosphate fertilizer. If it is nickel free. These sludge will consume a lot of caustic to neutralize.

7. EXTENTION OF THE LIFE OF CHEMICAL BATH. The removal of sludge will eliminate at the tank bottom. On line removal of iron sludge from the chemical bath will increase the life of the chemical bath. As the life of the bath is also determined by the chemistry of the presence of the iron in the solution the exact increase in life may not be estimated.

Product Description

Unique features of SARTIME Oil Separator

It separates not only oil but also the sludge formed in the degreasing tank.

Advantages of Online Total Oil-Sludge Separation System

TOS keeps the bath consistently clean by removing oil & soil continuously while extending bath life to more than 13 months, in one case as long as 4 years.

1. QUALITY IMPROVEMENT IN FINISHING In the absence of On line Vat Sludge Separating system there will be no air agitation to the chemical baths. Since the sludge generation is removed on line Air agitation can be provided which will enable chemical to mix evenly and will not settle at the bottom. This will improve the finishing. Reduced usage of chemical for the same quantity of products results in reduce waste generation. We have seen rejections coming down by 70%.

2. CONSISTANCY IN QUALITY There will be no Monday quality and Friday quality. There will not be any powder formation & the finishing will be good.

3. IMPLEMENTATION OF KAIZAN & 6 SIGMA EASIER. Since the implementation of VSS is aimed at reducing the waste generation, Improvement in quality & elimination of stoppage of production for maintenance, this will contributes in achieving standards in Kaizan & 6 Sigmas.

4. REDUCTION OF CHEMICAL CONSUMPTION. Since no weekly cleaning is required, VSS will reduce the chemical wastage or consumption hence reduction of chemical usage. This is expected to be about 5%.

5. ELIMINATION OF PRODUCTION STOPPAGE FOR CLEANING. Implementation of On line Vat Sludge separating system will not require weekly cleaning of the chemical tank, which normally takes one shift loss. This will eliminate the one shift production loss. Besides other loss like power used for heating etc., due to keep the plant out of production will be eliminated.

6. E.T.P PROBLEMS REDUCED. Since the sludge is stored separately, this can be used as a phosphate fertilizer. If it is nickel free. These sludge will consume a lot of caustic to neutralize.

7. EXTENTION OF THE LIFE OF CHEMICAL BATH. The removal of sludge will eliminate at the tank bottom. On line removal of iron sludge from the chemical bath will increase the life of the chemical bath. As the life of the bath is also determined by the chemistry of the presence of the iron in the solution the exact increase in life may not be estimated.

It separates not only oil but also the sludge formed in the degreasing tank.

Advantages of Online Total Oil-Sludge Separation System

TOS keeps the bath consistently clean by removing oil & soil continuously while extending bath life to more than 13 months, in one case as long as 4 years.

1. QUALITY IMPROVEMENT IN FINISHING In the absence of On line Vat Sludge Separating system there will be no air agitation to the chemical baths. Since the sludge generation is removed on line Air agitation can be provided which will enable chemical to mix evenly and will not settle at the bottom. This will improve the finishing. Reduced usage of chemical for the same quantity of products results in reduce waste generation. We have seen rejections coming down by 70%.

2. CONSISTANCY IN QUALITY There will be no Monday quality and Friday quality. There will not be any powder formation & the finishing will be good.

3. IMPLEMENTATION OF KAIZAN & 6 SIGMA EASIER. Since the implementation of VSS is aimed at reducing the waste generation, Improvement in quality & elimination of stoppage of production for maintenance, this will contributes in achieving standards in Kaizan & 6 Sigmas.

4. REDUCTION OF CHEMICAL CONSUMPTION. Since no weekly cleaning is required, VSS will reduce the chemical wastage or consumption hence reduction of chemical usage. This is expected to be about 5%.

5. ELIMINATION OF PRODUCTION STOPPAGE FOR CLEANING. Implementation of On line Vat Sludge separating system will not require weekly cleaning of the chemical tank, which normally takes one shift loss. This will eliminate the one shift production loss. Besides other loss like power used for heating etc., due to keep the plant out of production will be eliminated.

6. E.T.P PROBLEMS REDUCED. Since the sludge is stored separately, this can be used as a phosphate fertilizer. If it is nickel free. These sludge will consume a lot of caustic to neutralize.

7. EXTENTION OF THE LIFE OF CHEMICAL BATH. The removal of sludge will eliminate at the tank bottom. On line removal of iron sludge from the chemical bath will increase the life of the chemical bath. As the life of the bath is also determined by the chemistry of the presence of the iron in the solution the exact increase in life may not be estimated.

Export Countries

Germany

Zambia

Related Sectors

Design

Drugs & Pharmaceuticals

Engineering

Environment

Manufacturing

Petrochemicals

Web Link

About the Company

Established in 1990 at Chennai, Tamil Nadu, India, we Sartime Horological Private Limited, are one of the leading manufacturers and exporters of Water Purification Plants & Systems. The complete product range we offer include ETP, RO Plants, Evaporator, UF, SBR, Advanced Membrane Separation System and Oil Separators or Skimmers. Further, we also offer Phosphate Sludge Separator, Compost Aero Tiller, Auto Spraying System.

Backed by well developed R & D activities and process approach as well as services of experienced industry professionals allow us to maintain a well defined process approach in each of the project handled by us. Based at studying performance of each of the equipment, we arrive at some process modifications that are not commonly used in Pollution Control Industry.

We meet the plant technology customization needs of our customers To understand and meet the critical equipment management related to pollution We hold expertise in studying both process and treatment scheme by studying the process and arriving at ideas to cut down waste at source itself By studying performance of each of the equipment, we can arrive at some process modifications that are not commonly used in pollution control industry by virtue of our well developed R & D activities Our well defined business approach helps us improves performance far beyond the conventional approach.

We adopt technologies that reduce costs as well as pollution, helping companies to be better placed to stay ahead of the competition If client’s effluent treatment/pollution problem is not solved by addition of equipment or any other strategy, it’s time they get in touch with us. We hold expertise in solving difficult Pollution Problems that others can’t.

Backed by well developed R & D activities and process approach as well as services of experienced industry professionals allow us to maintain a well defined process approach in each of the project handled by us. Based at studying performance of each of the equipment, we arrive at some process modifications that are not commonly used in Pollution Control Industry.

We meet the plant technology customization needs of our customers To understand and meet the critical equipment management related to pollution We hold expertise in studying both process and treatment scheme by studying the process and arriving at ideas to cut down waste at source itself By studying performance of each of the equipment, we can arrive at some process modifications that are not commonly used in pollution control industry by virtue of our well developed R & D activities Our well defined business approach helps us improves performance far beyond the conventional approach.

We adopt technologies that reduce costs as well as pollution, helping companies to be better placed to stay ahead of the competition If client’s effluent treatment/pollution problem is not solved by addition of equipment or any other strategy, it’s time they get in touch with us. We hold expertise in solving difficult Pollution Problems that others can’t.

Login to see seller contact details.

Product Reviews

More products by SARTIME HOROLOGICAL (P) LTD