Inline Chrome Reduction of CR6----CR3

By SARTIME HOROLOGICAL (P) LTD

Inline Reduction of Cr6+ to Cr3- No toxic emission to air -No open Flash mixer & Flocculator- Treatment in closed Reactor.

60% Saving of SMBS, 40% Saving of Acid/Alkali, Space Saving (No storage tank required for collection and reaction

Process Overview

The reduction of hexavalent chromium [Cr(VI)] to trivalent chromium [Cr(III)] will decrease the mobility of chromium in the environment. The effort used sodium metabisulfite as the reducing agent. Sodium metabisulfite, when added to water, forms sodium bisulfite. In the presence of acid and Cr(VI), the sodium bisulfite has the following reaction.

First, hexavalent chromium, either in the form of chromate or dichromate, is reduced to trivalent chromium. Wastewater flows into the first reaction tank, where the pH is measured and acid is automatically brought into the process until a pH set point value in the acidic range is achieved. The reaction time is just a few minutes, and a lower pH for an even faster reaction would require considerably more acid. At the same time, the oxidation reduction potential (ORP) of the solution is measured, and sulfur sodium sulfite, or sodium metabisulfite is automatically injected until the ORP value is achieved.

Na2S2O5 + H2O 2NaHSO3

3NaHSO3 + 2H2CrO4 + 3H2SO4 Cr2(SO4)3 + 5H2O + 3NaHSO

After the hexavalent chromium is reduced to the trivalent state, it is then reacted with caustic to precipitate chromium hydroxide [Cr(OH)3].

Cr2(SO4)3 + 3NaOH 2Cr(OH)3 + 3Na2SO4

60% Saving of SMBS, 40% Saving of Acid/Alkali, Space Saving (No storage tank required for collection and reaction

Process Overview

The reduction of hexavalent chromium [Cr(VI)] to trivalent chromium [Cr(III)] will decrease the mobility of chromium in the environment. The effort used sodium metabisulfite as the reducing agent. Sodium metabisulfite, when added to water, forms sodium bisulfite. In the presence of acid and Cr(VI), the sodium bisulfite has the following reaction.

First, hexavalent chromium, either in the form of chromate or dichromate, is reduced to trivalent chromium. Wastewater flows into the first reaction tank, where the pH is measured and acid is automatically brought into the process until a pH set point value in the acidic range is achieved. The reaction time is just a few minutes, and a lower pH for an even faster reaction would require considerably more acid. At the same time, the oxidation reduction potential (ORP) of the solution is measured, and sulfur sodium sulfite, or sodium metabisulfite is automatically injected until the ORP value is achieved.

Na2S2O5 + H2O 2NaHSO3

3NaHSO3 + 2H2CrO4 + 3H2SO4 Cr2(SO4)3 + 5H2O + 3NaHSO

After the hexavalent chromium is reduced to the trivalent state, it is then reacted with caustic to precipitate chromium hydroxide [Cr(OH)3].

Cr2(SO4)3 + 3NaOH 2Cr(OH)3 + 3Na2SO4

Product Description

Inline Reduction of Cr6+ to Cr3- No toxic emission to air -No open Flash mixer & Flocculator- Treatment in closed Reactor.

60% Saving of SMBS, 40% Saving of Acid/Alkali, Space Saving (No storage tank required for collection and reaction

Process Overview

The reduction of hexavalent chromium [Cr(VI)] to trivalent chromium [Cr(III)] will decrease the mobility of chromium in the environment. The effort used sodium metabisulfite as the reducing agent. Sodium metabisulfite, when added to water, forms sodium bisulfite. In the presence of acid and Cr(VI), the sodium bisulfite has the following reaction.

First, hexavalent chromium, either in the form of chromate or dichromate, is reduced to trivalent chromium. Wastewater flows into the first reaction tank, where the pH is measured and acid is automatically brought into the process until a pH set point value in the acidic range is achieved. The reaction time is just a few minutes, and a lower pH for an even faster reaction would require considerably more acid. At the same time, the oxidation reduction potential (ORP) of the solution is measured, and sulfur sodium sulfite, or sodium metabisulfite is automatically injected until the ORP value is achieved.

Na2S2O5 + H2O 2NaHSO3

3NaHSO3 + 2H2CrO4 + 3H2SO4 Cr2(SO4)3 + 5H2O + 3NaHSO

After the hexavalent chromium is reduced to the trivalent state, it is then reacted with caustic to precipitate chromium hydroxide [Cr(OH)3].

Cr2(SO4)3 + 3NaOH 2Cr(OH)3 + 3Na2SO4

60% Saving of SMBS, 40% Saving of Acid/Alkali, Space Saving (No storage tank required for collection and reaction

Process Overview

The reduction of hexavalent chromium [Cr(VI)] to trivalent chromium [Cr(III)] will decrease the mobility of chromium in the environment. The effort used sodium metabisulfite as the reducing agent. Sodium metabisulfite, when added to water, forms sodium bisulfite. In the presence of acid and Cr(VI), the sodium bisulfite has the following reaction.

First, hexavalent chromium, either in the form of chromate or dichromate, is reduced to trivalent chromium. Wastewater flows into the first reaction tank, where the pH is measured and acid is automatically brought into the process until a pH set point value in the acidic range is achieved. The reaction time is just a few minutes, and a lower pH for an even faster reaction would require considerably more acid. At the same time, the oxidation reduction potential (ORP) of the solution is measured, and sulfur sodium sulfite, or sodium metabisulfite is automatically injected until the ORP value is achieved.

Na2S2O5 + H2O 2NaHSO3

3NaHSO3 + 2H2CrO4 + 3H2SO4 Cr2(SO4)3 + 5H2O + 3NaHSO

After the hexavalent chromium is reduced to the trivalent state, it is then reacted with caustic to precipitate chromium hydroxide [Cr(OH)3].

Cr2(SO4)3 + 3NaOH 2Cr(OH)3 + 3Na2SO4

Export Countries

Germany

Related Sectors

Chemicals

Design

Drugs & Pharmaceuticals

Petrochemicals

Water

Web Link

About the Company

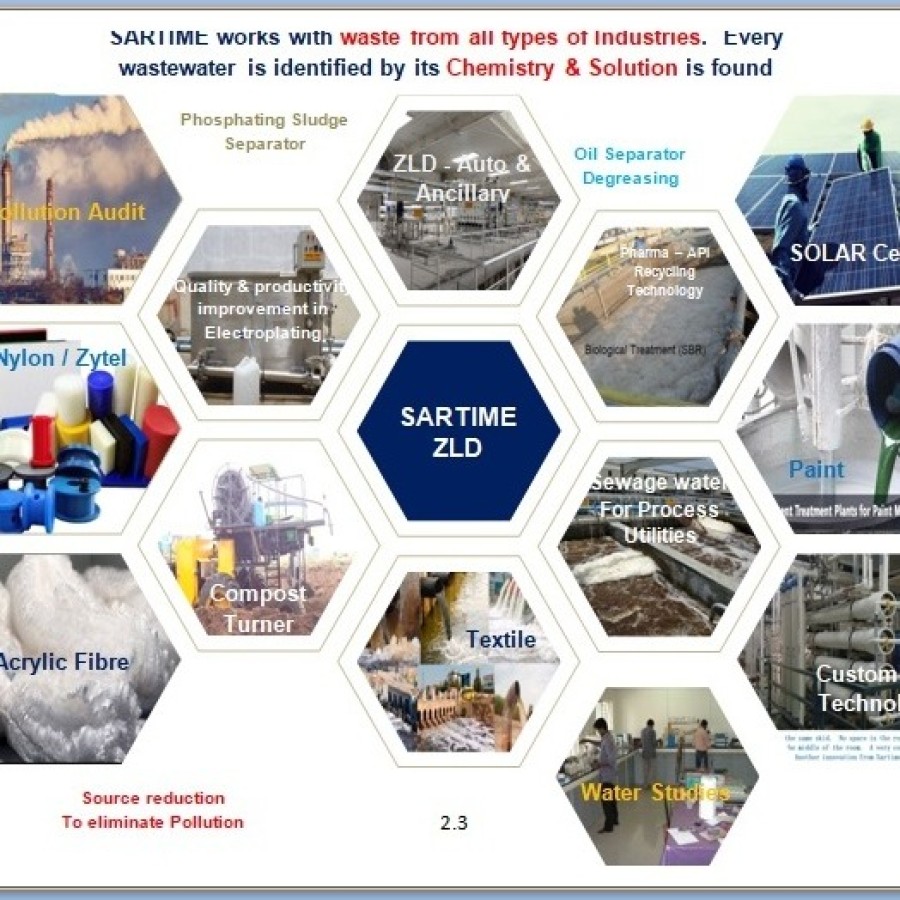

Established in 1990 at Chennai, Tamil Nadu, India, we Sartime Horological Private Limited, are one of the leading manufacturers and exporters of Water Purification Plants & Systems. The complete product range we offer include ETP, RO Plants, Evaporator, UF, SBR, Advanced Membrane Separation System and Oil Separators or Skimmers. Further, we also offer Phosphate Sludge Separator, Compost Aero Tiller, Auto Spraying System.

Backed by well developed R & D activities and process approach as well as services of experienced industry professionals allow us to maintain a well defined process approach in each of the project handled by us. Based at studying performance of each of the equipment, we arrive at some process modifications that are not commonly used in Pollution Control Industry.

We meet the plant technology customization needs of our customers To understand and meet the critical equipment management related to pollution We hold expertise in studying both process and treatment scheme by studying the process and arriving at ideas to cut down waste at source itself By studying performance of each of the equipment, we can arrive at some process modifications that are not commonly used in pollution control industry by virtue of our well developed R & D activities Our well defined business approach helps us improves performance far beyond the conventional approach.

We adopt technologies that reduce costs as well as pollution, helping companies to be better placed to stay ahead of the competition If client’s effluent treatment/pollution problem is not solved by addition of equipment or any other strategy, it’s time they get in touch with us. We hold expertise in solving difficult Pollution Problems that others can’t.

Backed by well developed R & D activities and process approach as well as services of experienced industry professionals allow us to maintain a well defined process approach in each of the project handled by us. Based at studying performance of each of the equipment, we arrive at some process modifications that are not commonly used in Pollution Control Industry.

We meet the plant technology customization needs of our customers To understand and meet the critical equipment management related to pollution We hold expertise in studying both process and treatment scheme by studying the process and arriving at ideas to cut down waste at source itself By studying performance of each of the equipment, we can arrive at some process modifications that are not commonly used in pollution control industry by virtue of our well developed R & D activities Our well defined business approach helps us improves performance far beyond the conventional approach.

We adopt technologies that reduce costs as well as pollution, helping companies to be better placed to stay ahead of the competition If client’s effluent treatment/pollution problem is not solved by addition of equipment or any other strategy, it’s time they get in touch with us. We hold expertise in solving difficult Pollution Problems that others can’t.

Login to see seller contact details.

Product Reviews

More products by SARTIME HOROLOGICAL (P) LTD