Parboiling and Drying System (PBD)

By MILLTEC MACHINERY PVT LTD

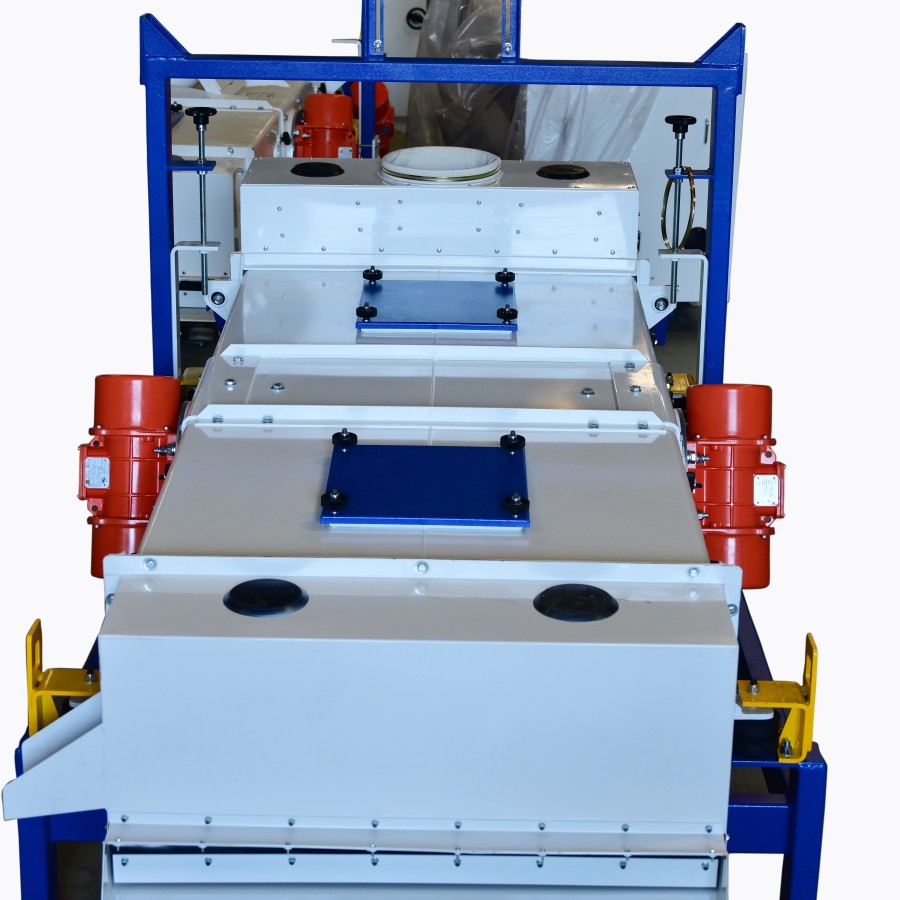

AGI Milltec offers advanced parboiling and drying solutions to enhance rice milling efficiency and grain quality.

Parboiling is a hydrothermal process performed in three steps: soaking, steaming, and drying. It causes starch gelatinization, where amylose molecules re-associate, forming a tightly packed structure that mends endosperm cracks, increases translucency and hardness, reduces chalkiness, and minimizes breakage.

After parboiling, the paddy is dried to achieve the ideal moisture level of 14% for optimal milling. AGI Milltec provides LSU dryers with both batch and continuous drying options, ensuring efficient and precise drying for superior results.

Parboiling is a hydrothermal process performed in three steps: soaking, steaming, and drying. It causes starch gelatinization, where amylose molecules re-associate, forming a tightly packed structure that mends endosperm cracks, increases translucency and hardness, reduces chalkiness, and minimizes breakage.

After parboiling, the paddy is dried to achieve the ideal moisture level of 14% for optimal milling. AGI Milltec provides LSU dryers with both batch and continuous drying options, ensuring efficient and precise drying for superior results.

Keywords :

Drying

Parboiling

Parboiling and drying

Pbd

Rpd

- CATEGORIES : Food & Beverages Cereals & Food Grains Parboiled Rice

Product Description

AGI Milltec offers advanced parboiling and drying solutions to enhance rice milling efficiency and grain quality.

Parboiling is a hydrothermal process performed in three steps: soaking, steaming, and drying. It causes starch gelatinization, where amylose molecules re-associate, forming a tightly packed structure that mends endosperm cracks, increases translucency and hardness, reduces chalkiness, and minimizes breakage.

After parboiling, the paddy is dried to achieve the ideal moisture level of 14% for optimal milling. AGI Milltec provides LSU dryers with both batch and continuous drying options, ensuring efficient and precise drying for superior results.

Parboiling is a hydrothermal process performed in three steps: soaking, steaming, and drying. It causes starch gelatinization, where amylose molecules re-associate, forming a tightly packed structure that mends endosperm cracks, increases translucency and hardness, reduces chalkiness, and minimizes breakage.

After parboiling, the paddy is dried to achieve the ideal moisture level of 14% for optimal milling. AGI Milltec provides LSU dryers with both batch and continuous drying options, ensuring efficient and precise drying for superior results.

Export Countries

Australia

Bangladesh

Belgium

Bhutan

Brazil

Egypt

Fiji

Georgia

Ghana

Honduras

India

Indonesia

Related Sectors

Food Processing

Web Link

Certification

ISO 45001:2018, ISO14001:2015, ISO9001:2015, BIS – 17853-2022 – CM/L - 6200192904 for FRK

Major Buyers

rice millers, MILLERS

Availability

Available

Brand

AGI MILLTEC

About the Company

Brijendra Singh Bhadauria, AB Agro Industries

AGI Milltec has commissioned a 12 TPH rice mill along with a 96-ton-per-batch / 192-ton-per-day parboiling and steaming plant, featuring online cooker and automation. The fit and finish of the PBD and all machines are excellent, reflecting high manufacturing standards. We are extremely pleased with both the equipment and the service provided. The rice quality stands out with its uniform colour, smooth polish, and low broken percentage. The AGI Milltec team delivered the machines on time, set everything up perfectly, and provided solid after-sales service. We are fully satisfied and confidently recommend AGI Milltec to anyone looking for reliable and high-quality rice processing unit.”

Login to see seller contact details.

Product Reviews

More products by MILLTEC MACHINERY PVT LTD