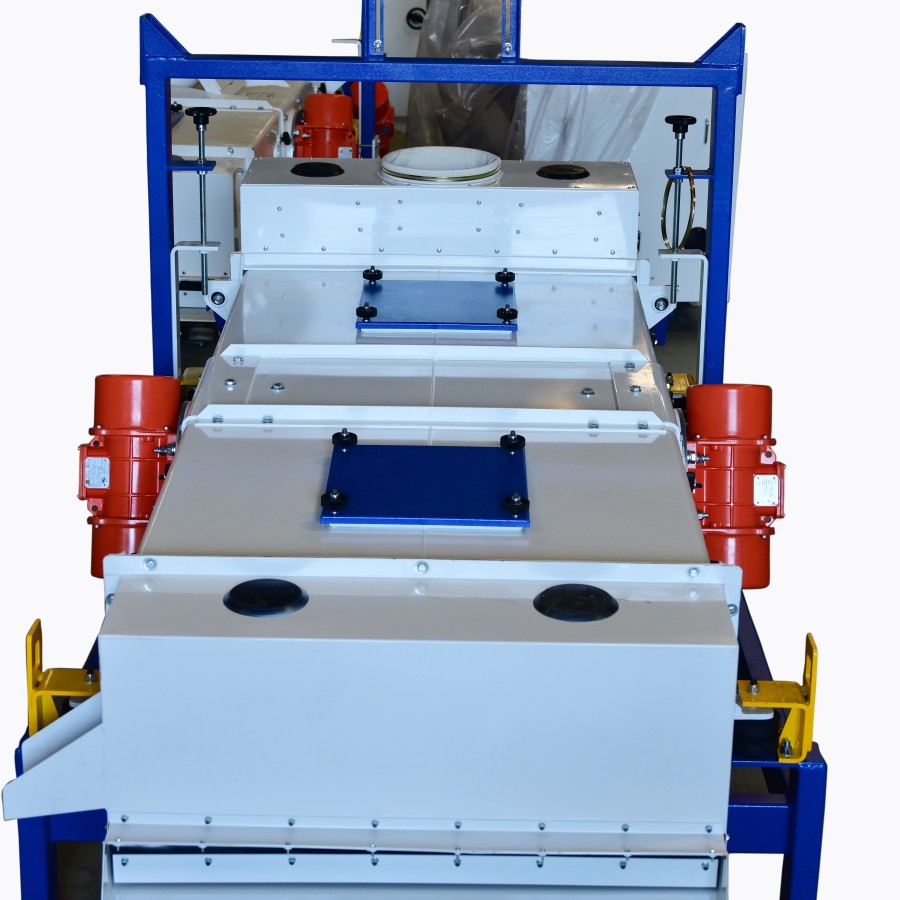

Pneumatic Sheller

By MILLTEC MACHINERY PVT LTD

AGI Milltec Pneumatic Sheller is your best choice for efficient husk removal from paddy grains. Engineered for precision and performance, this state-of-the-art machine delivers an impressive 95% husk removal accuracy. Explore the exceptional features and advantages that make this pneumatic sheller a game-changer in grain processing.

Key Features

Precision husk removal

A dual counter-revolving roller system provides flawless husk removal, ensuring the purity of your grains.

Automatic control

Regulates roller pressure and feed rates to consistently deliver high-quality results, and minimize grain damage.

Pneumatic control

Enjoy unparalleled processing flexibility by adjusting shelling degree through compressed air pressure control.

Sensor-enabled panel

For added safety and convenience, the panel automatically disengages the rubber rollers when product flow stops.

Built-in cooling system

Dissipates heat during operation, extending the life of the rubber rollers.

Auto/manual mode

Choose from either automatic or manual operating modes, depending on your specific needs.

Extended roller life

Advanced design assures you of double the typical rubber roller lifespan, which helps to reduce maintenance costs.

Minimal grain breakage

Under normal conditions, our sheller minimizes grain breakage, preserving product quality.

Versatile applications

Suitable for processing raw rice, steam rice, and parboiled rice, and adaptable to various grain types.

Key Features

Precision husk removal

A dual counter-revolving roller system provides flawless husk removal, ensuring the purity of your grains.

Automatic control

Regulates roller pressure and feed rates to consistently deliver high-quality results, and minimize grain damage.

Pneumatic control

Enjoy unparalleled processing flexibility by adjusting shelling degree through compressed air pressure control.

Sensor-enabled panel

For added safety and convenience, the panel automatically disengages the rubber rollers when product flow stops.

Built-in cooling system

Dissipates heat during operation, extending the life of the rubber rollers.

Auto/manual mode

Choose from either automatic or manual operating modes, depending on your specific needs.

Extended roller life

Advanced design assures you of double the typical rubber roller lifespan, which helps to reduce maintenance costs.

Minimal grain breakage

Under normal conditions, our sheller minimizes grain breakage, preserving product quality.

Versatile applications

Suitable for processing raw rice, steam rice, and parboiled rice, and adaptable to various grain types.

Keywords :

Pneumatic Sheller

Sheller

- CATEGORIES : Food & Beverages Cereals & Food Grains Rice

Product Description

AGI Milltec Pneumatic Sheller is your best choice for efficient husk removal from paddy grains. Engineered for precision and performance, this state-of-the-art machine delivers an impressive 95% husk removal accuracy. Explore the exceptional features and advantages that make this pneumatic sheller a game-changer in grain processing.

Key Features

Precision husk removal

A dual counter-revolving roller system provides flawless husk removal, ensuring the purity of your grains.

Automatic control

Regulates roller pressure and feed rates to consistently deliver high-quality results, and minimize grain damage.

Pneumatic control

Enjoy unparalleled processing flexibility by adjusting shelling degree through compressed air pressure control.

Sensor-enabled panel

For added safety and convenience, the panel automatically disengages the rubber rollers when product flow stops.

Built-in cooling system

Dissipates heat during operation, extending the life of the rubber rollers.

Auto/manual mode

Choose from either automatic or manual operating modes, depending on your specific needs.

Extended roller life

Advanced design assures you of double the typical rubber roller lifespan, which helps to reduce maintenance costs.

Minimal grain breakage

Under normal conditions, our sheller minimizes grain breakage, preserving product quality.

Versatile applications

Suitable for processing raw rice, steam rice, and parboiled rice, and adaptable to various grain types.

Key Features

Precision husk removal

A dual counter-revolving roller system provides flawless husk removal, ensuring the purity of your grains.

Automatic control

Regulates roller pressure and feed rates to consistently deliver high-quality results, and minimize grain damage.

Pneumatic control

Enjoy unparalleled processing flexibility by adjusting shelling degree through compressed air pressure control.

Sensor-enabled panel

For added safety and convenience, the panel automatically disengages the rubber rollers when product flow stops.

Built-in cooling system

Dissipates heat during operation, extending the life of the rubber rollers.

Auto/manual mode

Choose from either automatic or manual operating modes, depending on your specific needs.

Extended roller life

Advanced design assures you of double the typical rubber roller lifespan, which helps to reduce maintenance costs.

Minimal grain breakage

Under normal conditions, our sheller minimizes grain breakage, preserving product quality.

Versatile applications

Suitable for processing raw rice, steam rice, and parboiled rice, and adaptable to various grain types.

Export Countries

India

Related Sectors

Food Processing

Certification

ISO 45001:2018, ISO14001:2015, ISO9001:2015, BIS – 17853-2022 – CM/L - 6200192904 for FRK

Major Buyers

rice millers, MILLERS

Availability

Available

Brand

AGI MILLTEC

About the Company

Login to see seller contact details.

Product Reviews

More products by MILLTEC MACHINERY PVT LTD